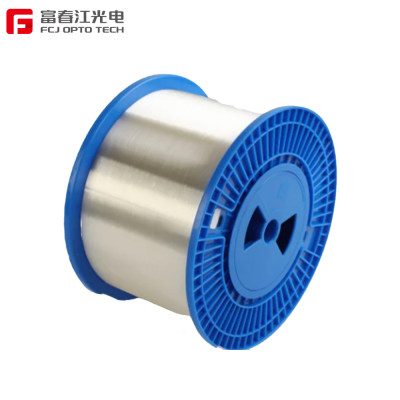

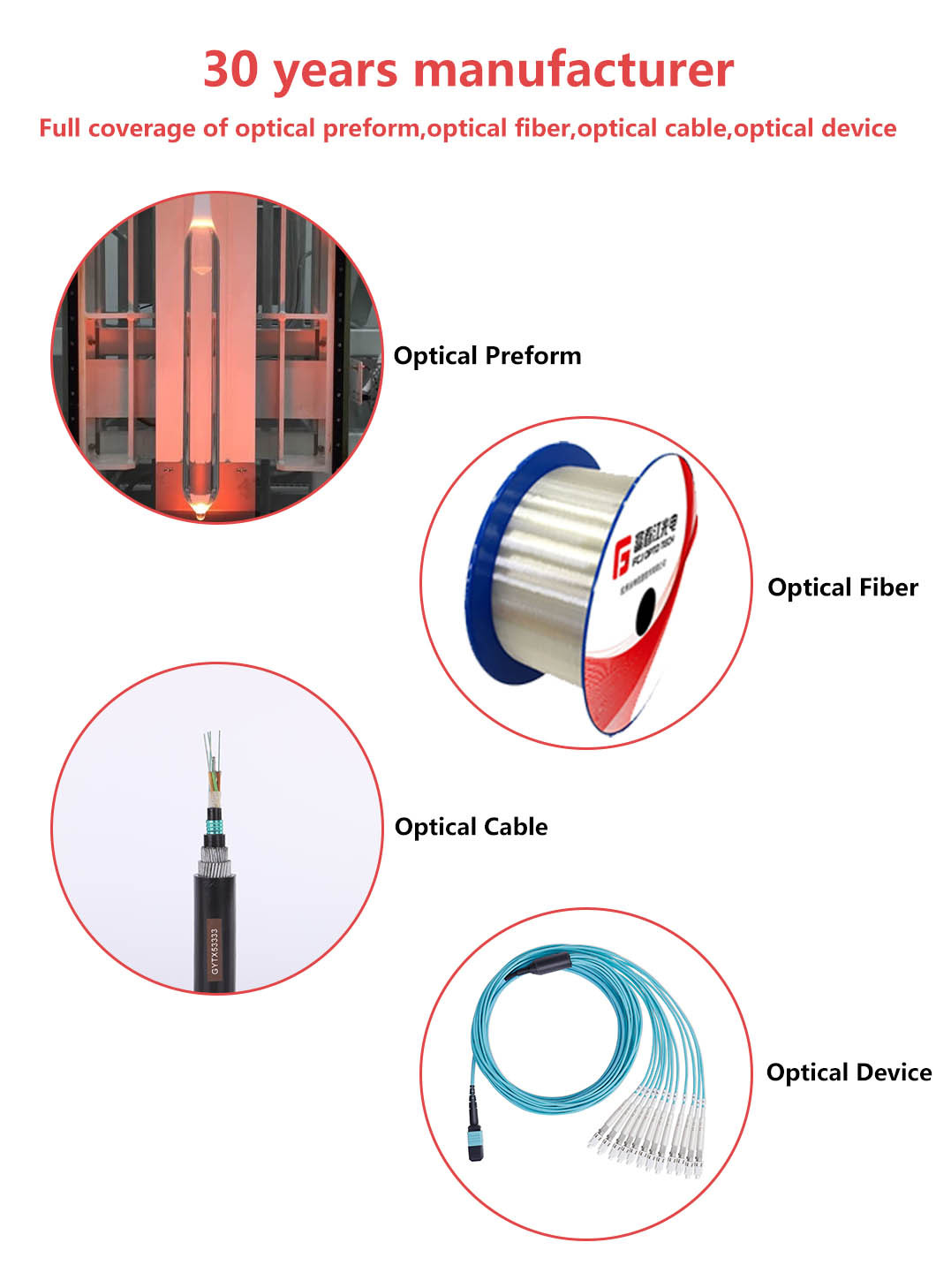

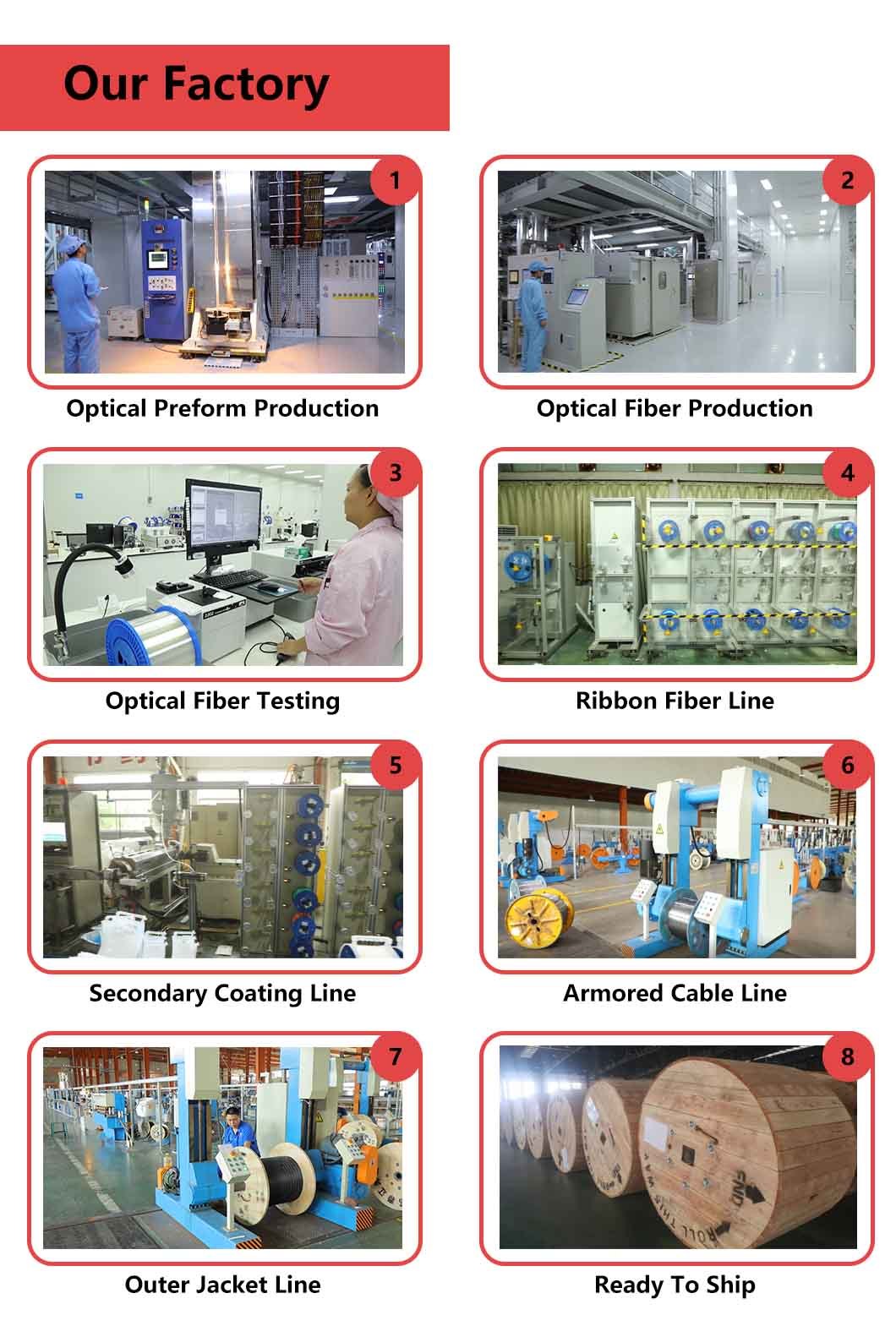

FCJ factory OM2 Bend Insensitive Multimode Fibre (50/125㎛) for Local area networks

FCJ factory OM2 Bend Insensitive Multimode Fibre (50/125㎛) for Local area networks

FCJ OPTO TECH OM2(50/125㎛) Bend Insensitive Multimode Fibre complies with or exceeds ISO/IEC 11801-1 OM2 specification, IEC 60793-2-10 A1-OM2 specification, and TIA-492AAAF A1-OM2 specification.

Features | Benefits and Applications |

Superior geometry uniformity Low attenuation High bandwidth at wavelengths of 850nm and 1300nm Manufactured by PCVD process Extremely refined refractive index profile | Local area networks (LAN) Video, voice and data services Gigabit Ethernet using laser or LED light sources |

Very low macro-bending sensitivity | Supports the use and installation of optical cables with a small bending radius |

Coated with FCJ's proprietary dual layer UV curable acrylate | High resistance to micro-bending Optimized performance in tight-buffer cable applications Stable performance over a wide range of environmental conditions |

Characteristics | Conditions | Specified values | Units |

Geometry Characteristics | |||

Core Diameter | - | 50±2.5 | [㎛] |

CoreNon-Circularity | - | ≤5.0 | [%] |

Cladding Diameter | - | 125.0±1.0 | [㎛] |

Cladding Non-Circularity | - | ≤1.0 | [%] |

Coating Diameter | - | 245±7 | [㎛] |

Coating/Cladding Concentricity Error | - | ≤10.0 | [㎛] |

Coating Non-Circularity | - | ≤6.0 | [%] |

Core/Cladding Concentricity Error | - | ≤1.5 | [㎛] |

Delivery Length | - | up to 17.6 | [km/reel] |

Optical Characteristics | |||

Attenuation | 850nm | ≤2.3 | [dB/km] |

| 1300nm | ≤0.6 | [dB/km] |

Overfilled Modal Bandwidth | 850nm | ≥500 | [MHz-km] |

| 1300nm | ≥500 | [MHz-km] |

Numerical Aperture | - | 0.200±0.015 | - |

Group Refractive Index | 850nm | 1.482 | - |

| 1300nm | 1.477 | - |

Zero Dispersion Wavelength,λ0 | - | 1295-1340 | [nm] |

Zero Dispersion Slope, S0 | 1295nm≤λ0≤1310nm | ≤0.105 | [ps/(nm2-km)] |

| 1310nm≤λ0≤1340nm | ≤0.000375 (1590-λ0) | [ps/(nm2-km)] |

Macrobending Loss | — | - | - |

2Turns @ 15 mm Radius | 850nm | ≤0.1 | [dB] |

| 1300nm | ≤0.3 | [dB] |

2Turns @7.5 mm Radius | 850nm | ≤0.2 | [dB] |

| 1300nm | ≤0.5 | [dB] |

Backscatter Characteristics 1300nm | |||

Step (Mean of Bidirectional Measurement) | — | ≤0.10 | [dB] |

Irregularities Over Fibre Length and Point Discontinuity |

| ≤0.10 | [dB] |

Attenuation Uniformity | - | ≤0.08 | [dB/km] |

Environmental Characteristics 850nm & 1300nm | |||

Temperature Cycling | -60°C to 85°C | ≤0.10 | [dB/km] |

Temperature-Humidity Cycling | -10°C to 85°C,4% to 98%RH | ≤0.10 | [dB/km] |

Water Immersion | 23°C,30days | ≤0.10 | [dB/km] |

Dry Heat | 85°C,30days | ≤0.10 | [dB/km] |

Damp Heat | 85°C,85% RH, 30 days | ≤0.10 | [dB/km] |

Mechanical Specification | |||

Proof Test | - | ≥9.0 | [N] |

| - | ≥1.0 | [%] |

| - | ≥100 | [kpsi] |

Coating Strip Force | typical average force | 1.5 | [N] |

| peak force | ≥3, ≤8.9 | [N] |

Dynamic Stress Corrosion Susceptibility Parameter (nd, typical) | - | 20 | - |

- Loading...

- *Title

- *Content